Mixer for battery mass production

One among the biggest challenges in the last 10 years is how to maintain a sustainable growth, while preserving the resources of our planet earth.

Forecasts indicate that we will use 50% more energy in 2050 than we do today.

This requires a technological leap forward in battery production.

MIX tackles this technological evolution with a specialised technical team which has developed a range of Li-ion MIX mixers specifically designed for the production of battery masses.

The Li-ion Mix range is based on a solid know-how in the world of powder mixing, developed over more than 30 years of experience.

In the production of lithium-ion batteries, it is imperative to:

1) Avoid contamination of raw materials to achieve high battery quality.

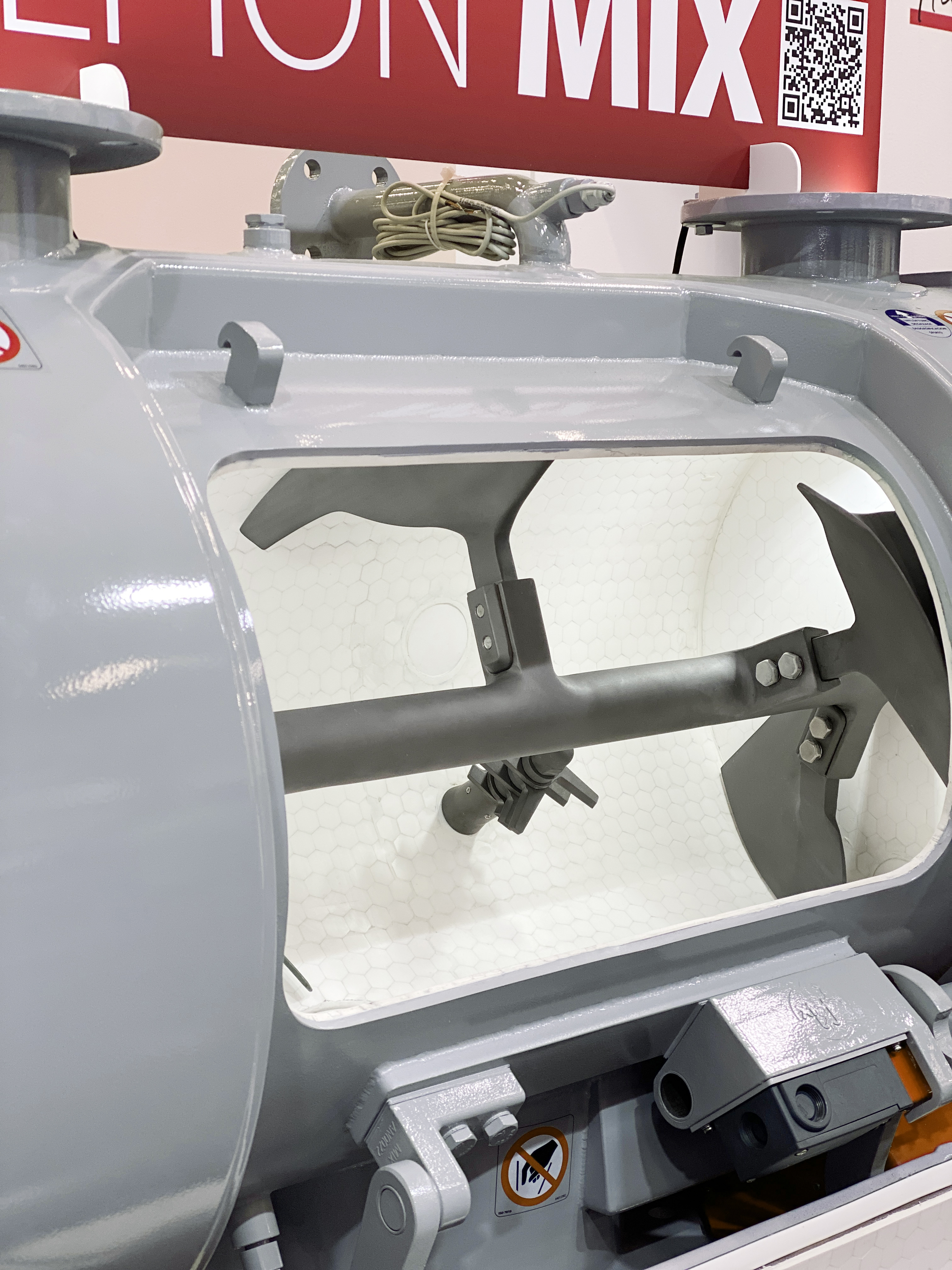

The mixing chamber of the Li-ion Mix is normally lined with a ceramic coating with alumina-based tiles, fixed by the use of a two-component epoxy resin.

Due to the complex geometry, the rotor shaft and mixing ploughshares can be coated with:

- two-component epoxy resin filled with ceramic powder

- thermal spray with alumina oxide (plasma spray)

- thermal spray with tungsten carbide HVOF

To meet specific requirements, alternative coatings such as ETFE / ECTFC are available.

2) Avoid dust leakage due to the possible toxicity and hazardousness of certain ingredients in the compounds.

Rotor shaft seals of the Li-ion Mix series are designed to guarantee a perfect seal and to minimise the wear caused by dust. They are radial seals without packing and sealing is ensured by a pressurised air barrier.

3) Achieving perfect homogenisation.

The presence of side choppers ensures proper dispersion of the micro-additives in the shortest possible time.

Li-ion Mix – constant evolution to meet today's challenges.